Clean Water Pipes

PRESMAK PVC U PRESSURE FROM 50 MM TO 400 MM CLEAN WATER PIPES

PRESMAK Plastic PVC Pressurized clean water pipes are produced in accordance with TS 274-e EN 1452-2, DIN 8061, DIN 8062 standards. Pressurized clean water pipes, which have health-compliant conditioning, are capable of withstanding underground and conditions.

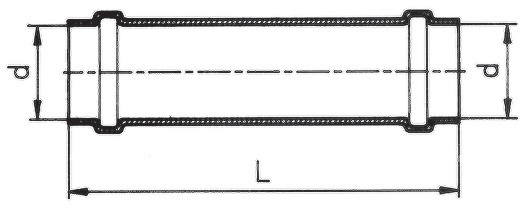

Pipes do not leave residue with their smooth and smooth inner surfaces. Therefore, they do not produce bacteria and smell. Pipes with an outer diameter of 50 mm and 400mm are produced with adhesive muf, plug muf and 6 meters standard length. It is resistant to 4,6,10,16 atm pressure. It is possible to produce different lengths upon request. Our pipes with 4 atm are not TSE and are manufactured according to the demands of the customers.

(mm) | (mm) | |

(mm) | (mm) | |

(mm) | (mm) | |

(mm) | (mm) | |

(mm) | (mm) | |

TECHNICAL CATALOG – USER MANUAL

1. Especially the bell parts should not be damaged while carrying the pipes.

2. It should be kept on a wooden chock and should be covered and protected from sunlight.

3. In the stacking of the pipes, you should be careful not to overlap especially the bellmouth parts and not to put too many pipes on top of each other. Because this causes the pipe to lose its ovality.

4. Before passing through the pipes, it must be examined.

5. When using pipes, it is recommended that pipes and fittings be laid with elastometric sealing gaskets.

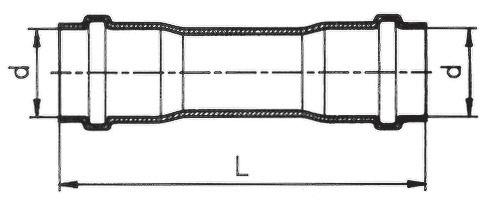

6. PRESMAK Plastic produces pressurized mufted parts so that they can easily pass outside the pipe of the same diameter. When adding, the rubber gasket should be placed in its slot for the muf.

7. After the appropriate lubricant is applied to the end of the pipe, the connection is made by placing it in the muf at the pipe head and rotating it slightly for a diameter and muf depth and pushing it until it opens slowly using a wooden block and crowbar.

8. Liquid soap should be used as a lubricant, taking into account the properties of the rubber gasket.

9. Do not use grease and so on so that the pipe can enter easily. oils are not used.

10. Indicates whether our pipes are guaranteed for 2 years.

ADDING AND LAYING OF PVC U PRESSURE PIPES

PVC Pressurized and other parts are lighter than the pipes and fittings of other features, so all terrain is used. The long-term performance of PVC U pressure pipelines is directly proportional to the quality of the pipes and additional materials used to lay the workmanship.

UNDERGROUND FLOORING

It is recommended to install pipes and fittings with elastomeric sealing gaskets. Pressmak Plastik Pressurized socket parts are produced in a way that they can easily pass outside the pipe of the same diameter. While attaching, the rubber gasket is placed in the slot made in the muf section. After the appropriate lubricant is applied to the end of the pipe, the pipe is placed into the muf at the head, rotated slightly for a diameter and muf depth and by pushing it down gently using a wooden block and crowbar. Liquid soap should be used as a lubricant, taking into account the properties of the rubber gasket.

For laying the pipes, see a recommended way of entering the pipe ends to be the same as the flow flow. The inner surfaces of the pipes should be kept clean for laying and splicing. Pipe closure to recommend that surface water and foreign objects enter the pipe at the completion of the work area and each working period.

It is calculated to add 40 cm to the pipe diameter. Cut sharp materials, corners and stones. If necessary, at least 0.1 m. Suitable bedding material to be brought from outside at height should be laid on the floor. The filling and bedding material to be used should not contain hard parts such as rock fragments, sharp and pointed stones, flint, clay soil, chalk and frozen soil. Thick sand, gravel and non-soil materials are suitable for filling and bedding. Arrange material should be placed in layers while filling the ditch.

Side fillings are made manually up to half the diameter of the pipe and compressed with a foot. Then, the filling is made to cover the upper part of the pipe and it is compressed again with the foot. The material is filled up to a height of 150 mm and it is made by machine from the sides so that it does not overlap the pipe. The necessary materials are placed for the remaining part of the filling and it is made by machine again without filling more than 250 mm height.

No direct correction is made on the pipe before a height of 300 mm. Designed for those up to 250 mm, it is for crushing with a foot or you can use it with pressure on the sides is a convenient way to provide adequate methods. After the layers to be created at a height of 150 mm, an upper compressed layer not less than 150 mm should be created. It should never be covered with concrete. Recommended minimum cover is 0.9 mm. This height will be sufficient in heavy traffic conditions and in areas with freezing risk according to local climatic conditions. This protective additional precautions should be taken and it will be buried so deep that the protective frost effect will not be seen.

Ferrous concrete blocks specially designed in all direction changes, empty (blind) ends in the elbows, large diameter reductions in order to transfer these forces to the sides of the trench, where they are subjected to pushing forces due to internal pressures.

FLOORING ON THE GROUND

It is recommended that the connections of PVC U pipe fittings or the connection methods made with the solvent-free adhesive of floored service lines are required. There are floors and other hard floor coverings for PVC coated floors. The bonding muff laid on the ground is opened by first marking the lengths of the joints that vary according to the boron joints. The pipe end is inserted into the glue-applied muf by rotating it until the mark disappears. Then it is to be turned slightly in the opposite direction and pulled back until the bell end is aligned.

It is not required for socket joint sealing in the pipeline. In this case, since it will crack, it must be insulated against frostbite. It is used between the metal clamps used at the support points and the pipes and from the flanges. The stresses are used according to the needs of the materials. It will be laid away from hot objects.

Installing PVC-U pipes underground or above ground should be without stress, and bending should be avoided by force. In long distances, small flexing of the pipeline in the horizontal plane in accordance with the ground can be considered normal.