Drilling Rig Pipes

PRESMAK PVC DRILLING EQUIPMENT PIPES UP TO 125 MM-330 MM

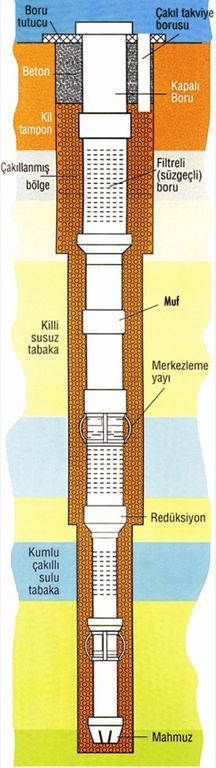

Drill pipes are manufactured in 2 types as filtered (slotted) and straight (closed). Filtered pipes are used in the permeable layer, and smooth pipes are used in the impermeable layer.

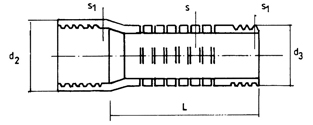

125mm – 330mm drilling reinforcement pipes are produced in a bellmouth system with the latest technology machines.

The filter slots are perpendicular to the frame pipe axis and 2mm wide. One end of the pipes is female and the other is male, with a trapezoidal thread, providing safe and easy connection.

KAPBOR

( " ) | (mm) | ||

( " ) | (mm) | TOLERANSLAR | |

100 mt. Up To The Depth

- Raw materials: PVC-U

- Length: 2 mt, 3mt ve 4 mt

- Filter Slit: 2 mm width perpendicular to the pipe axis

- Teeth: Trapezoid according to TS11794

- Connection: Female and male headed plug connection

- Marking: Standard marking

(mm) | ( " ) | (mm) | |

(mm) | ( " ) | (mm) | |

300 mt. Up To The Depth

- Raw materials: PVC-U

- Length: 2 mt, 3mt ve 4 mt

- Filter Slit: 2 mm width perpendicular to the pipe axis

- Teeth: Trapezoid according to TS11794

- Connection: Female and male headed plug connection

- Marking: Standard marking

(mm) | ( " ) | (mm) | |

(mm) | ( " ) | (mm) | |

PRESMAK PVC DRILLING TECHNICAL PIPES UP TO 125 mm-330 mm

User Guide – TECHNICAL CATALOG

Rules to be followed in the transportation and use of drill pipes:

While carrying the pipes (closed – filtered), especially the threaded parts should not be crashed.

Precautions should be taken against deformation in the pipes that will wait until usage and they should be protected from sunlight.

The male head should not be removed until the moment of use.

Pipes should be checked before use.

The diameter of the pump to be used must be suitable for the inside diameter of the pipe.

Appropriate tools such as a belt tightening wrench should be used when using the pipes.

Vertical shaft pumps or parts related to pump connections should be fitted to the well equipment pipe.

A centering spring should be used for the pipes to be placed vertically in the well.

Technical information should be used in the selection of well pipes.

Adhesive should not be applied to keep the pipe threads well. The glue melts the pipe and spoils the threads.

For easy entry of pipe threads, grease and so on. oils should not be used.

If the pipe is moving slowly while descending into the well, well mud should be filled into the pipe with a gun or bucket, and the pipe should not be hit.

If the pipe is attached to the well, it should not be driven back and released again. If the pipe does not descend, the well should be dredged with a drill and then the pipe should be lowered again.

After the pipe touches the bottom of the well, at least 10 cm. should be pulled up and suspended and kept suspended in order for the pipe to stand upright until the hammering is finished.

Apart from the PVC drilling equipment pipe, a sheet metal pipe should be placed at the well mouth and the pump should be fitted to this pipe. The pump should not be carried to the PVC equipment pipe.

The gravel should be thrown continuously with a shovel and evenly and regularly around the equipment pipe. Thus, the pipe is kept upright.

Particular attention should be paid that gravel does not make bridges in silty land.

Pipes that will wait until they are used should be placed on wooden wedges, covered and protected in the shade.

Scientific documentation and technical information should be used at every stage, from the drilling of wells to the selection of pipes.

In the stacking of the pipes, attention should be paid to avoid overlapping especially the bellmouth parts and not to put too many pipes on top of each other. This will cause the pipe to lose its ovality.

The 2-year warranty on our pipes is valid if the above mentioned issues are observed during use.